Textile Separator

4 January 2024

Plastic Sheet

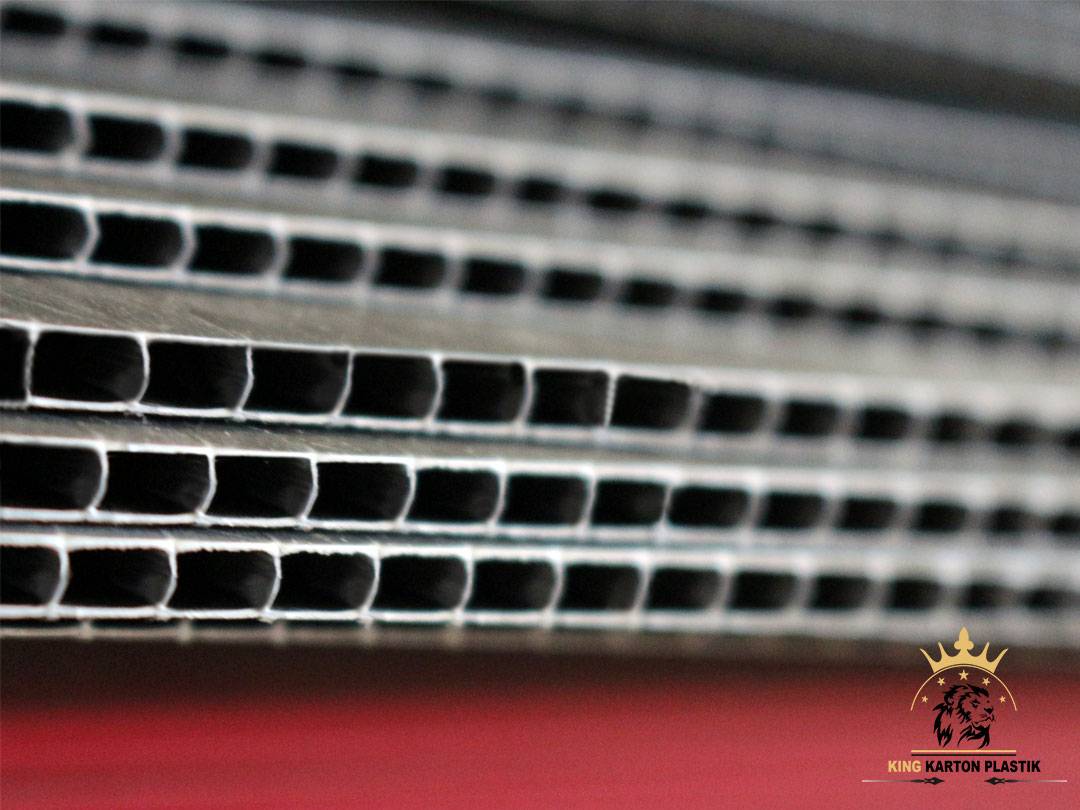

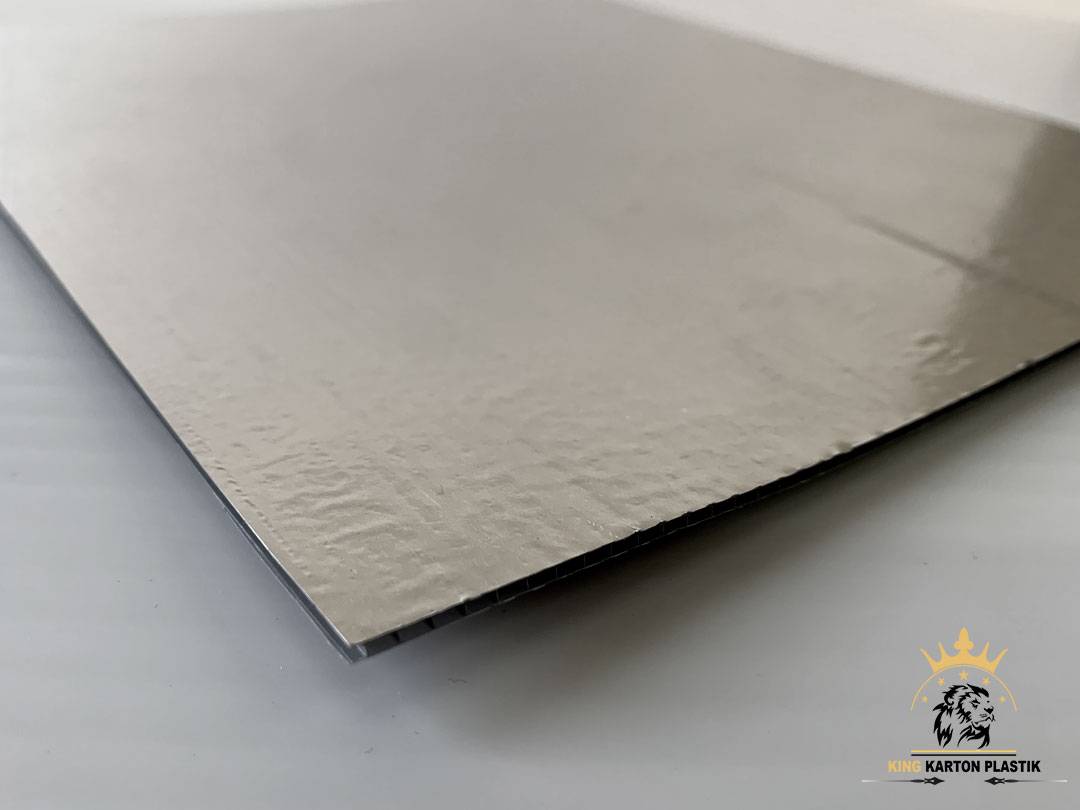

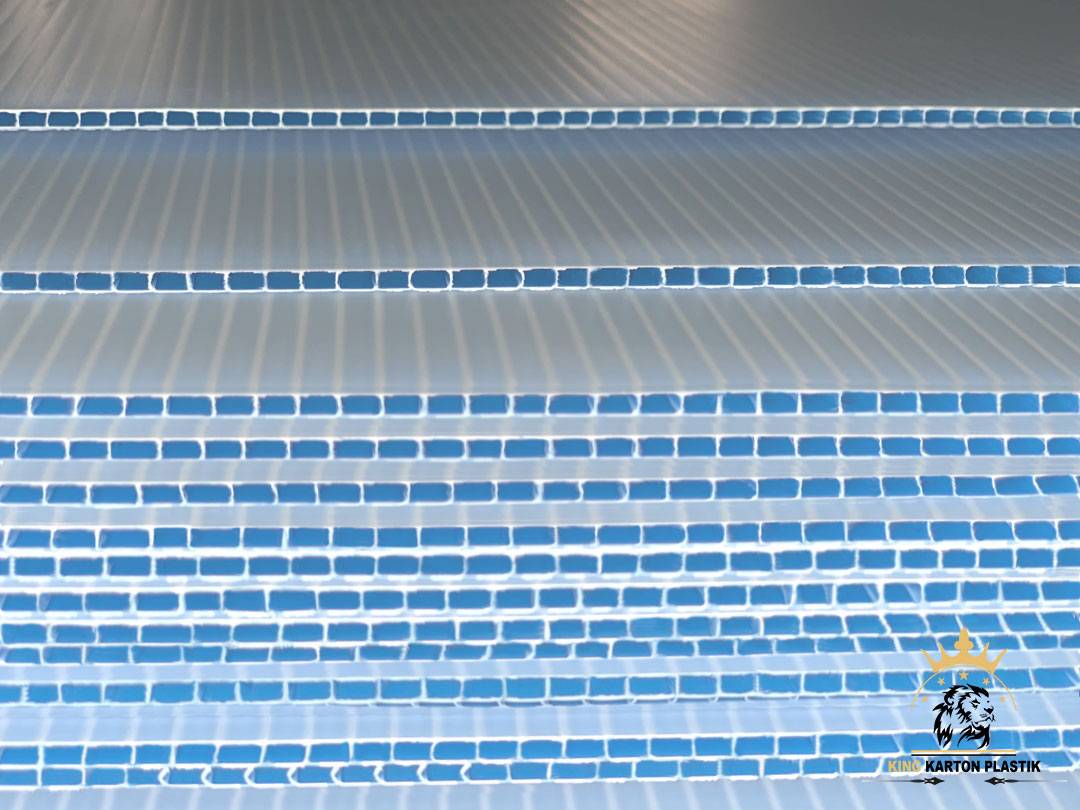

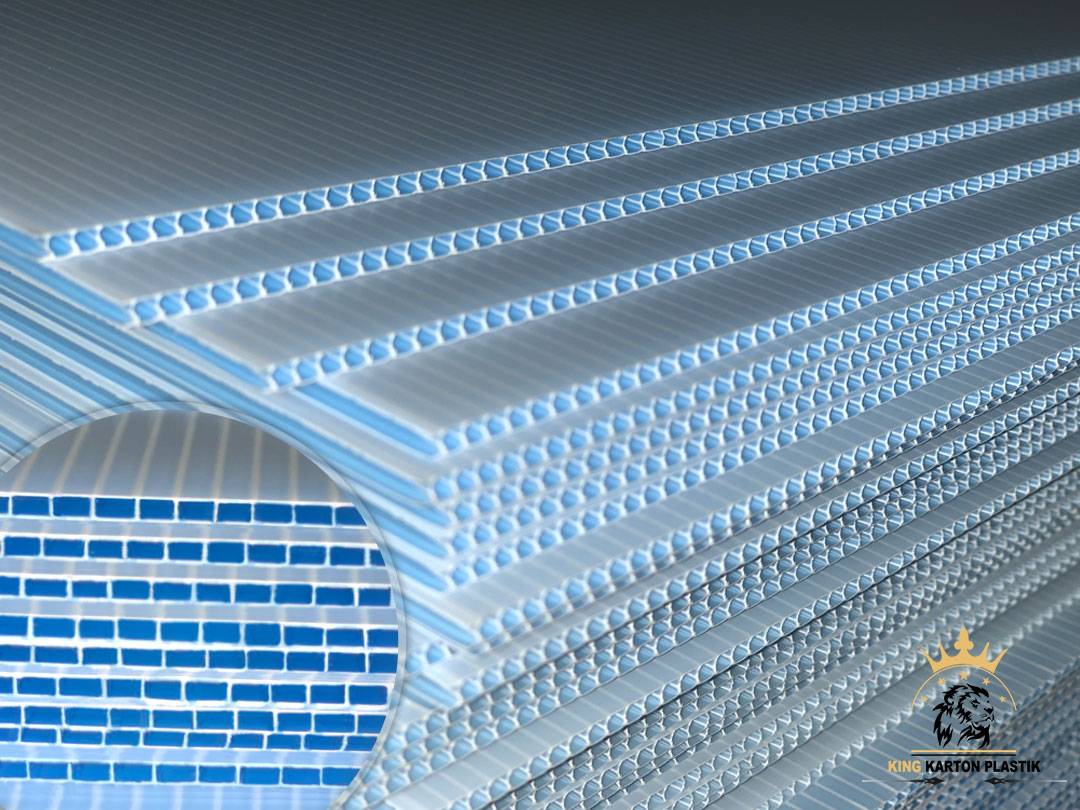

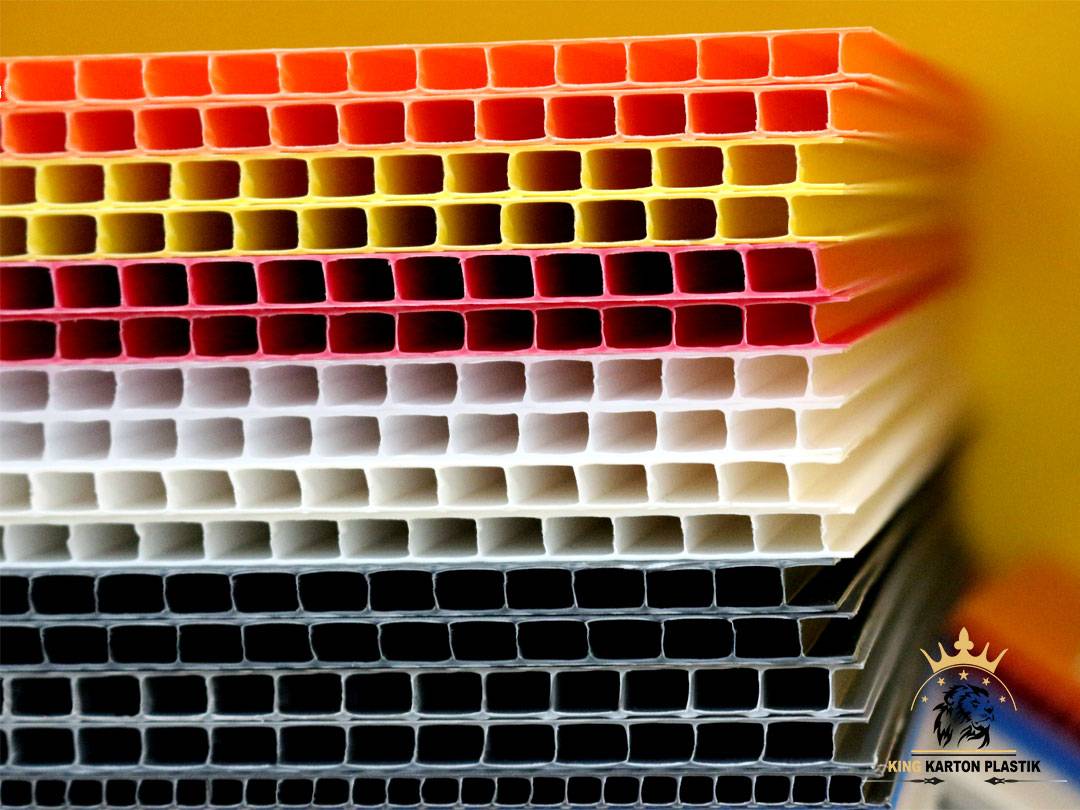

Plastic Sheet is a Plastic sheet made of three thin layers of polypropylene. This product is also known as a double-walled plastic sheet because a layer of corrugated and serrated plastic is placed between two flat sheets.

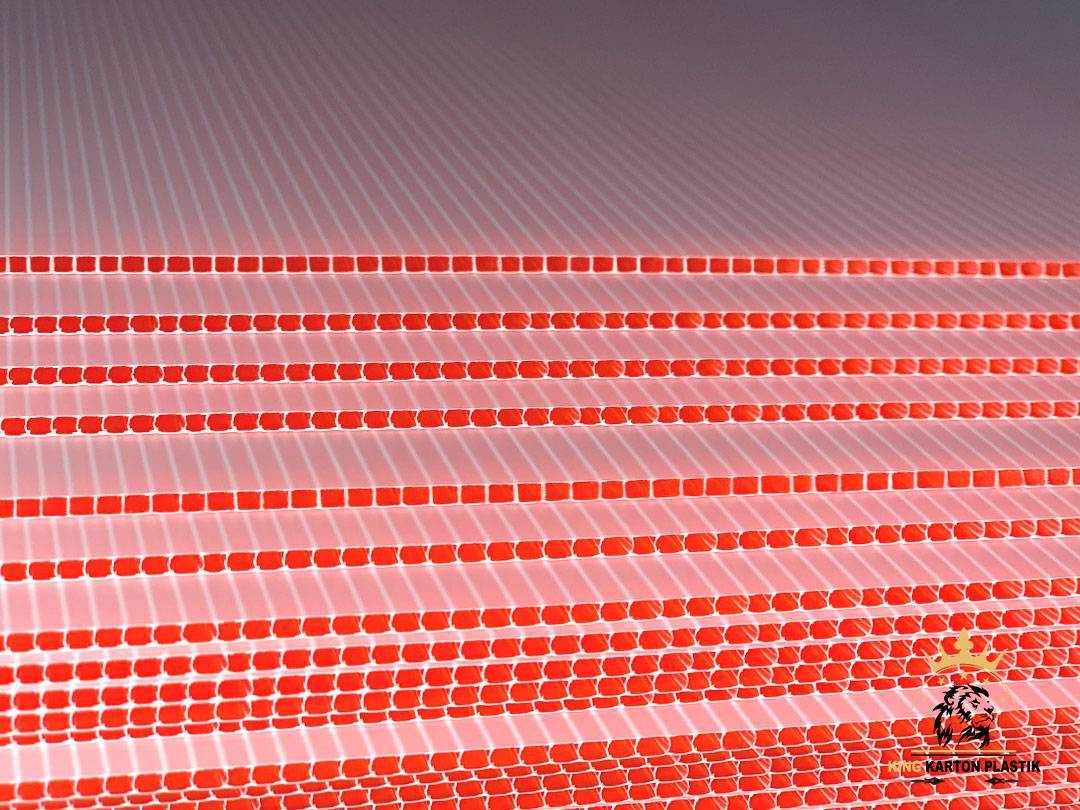

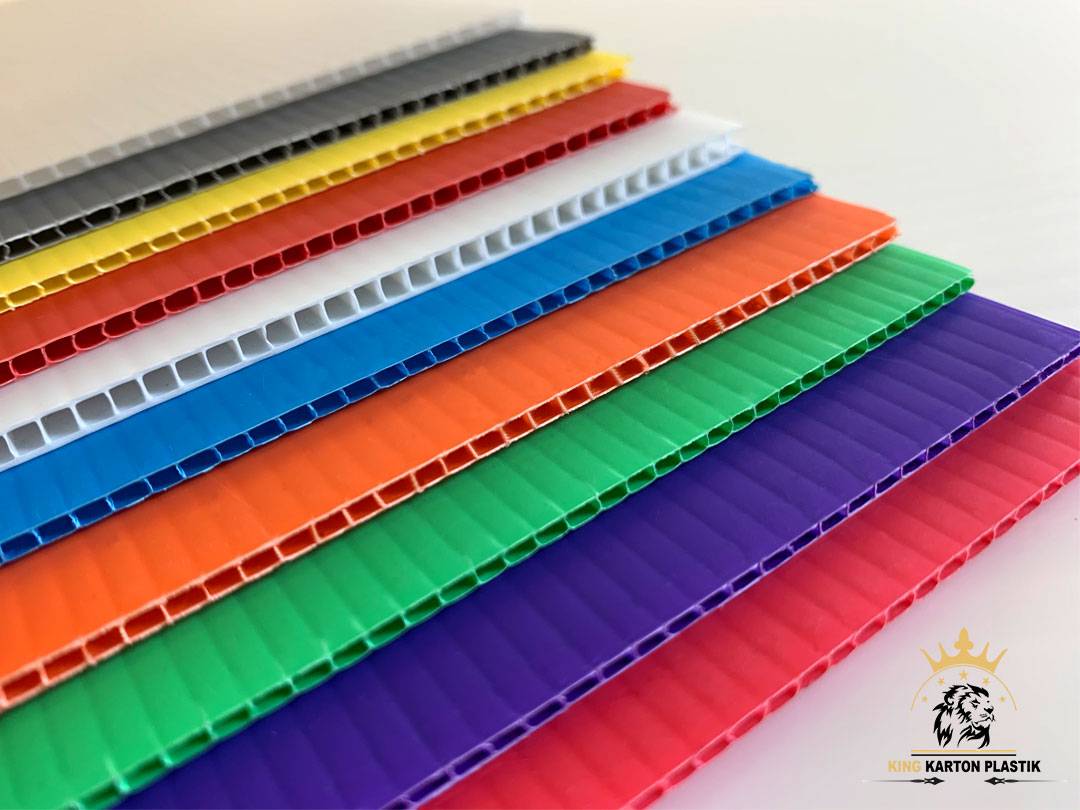

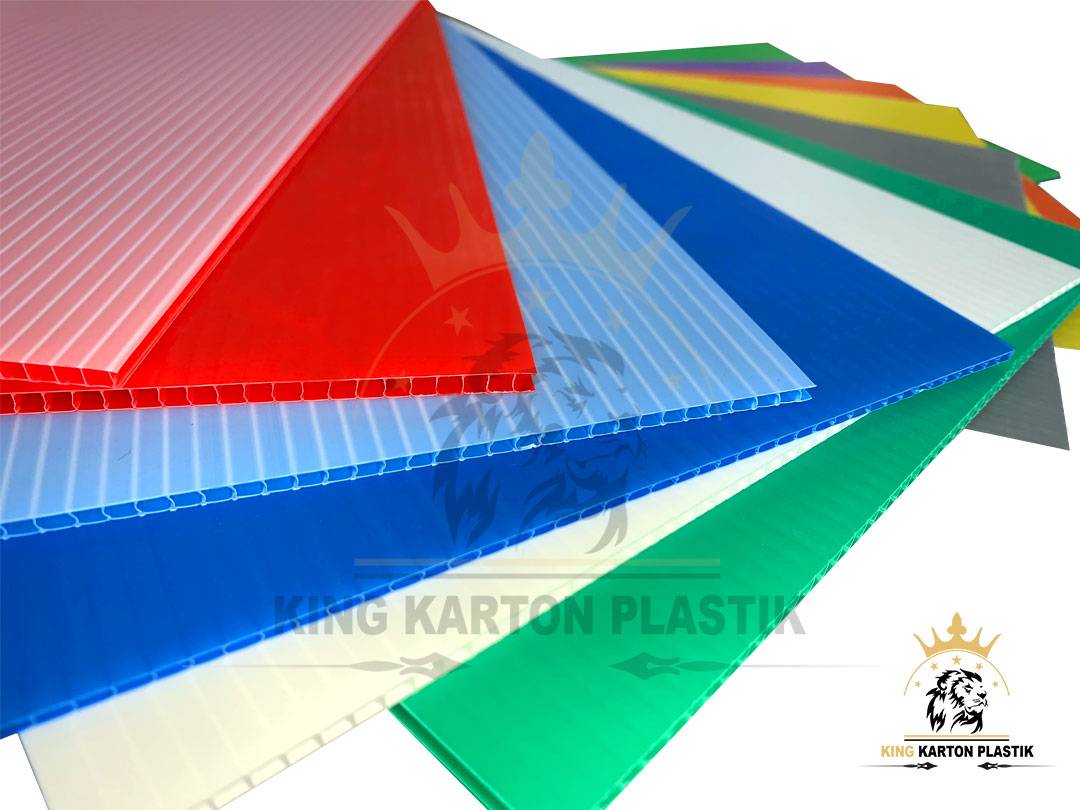

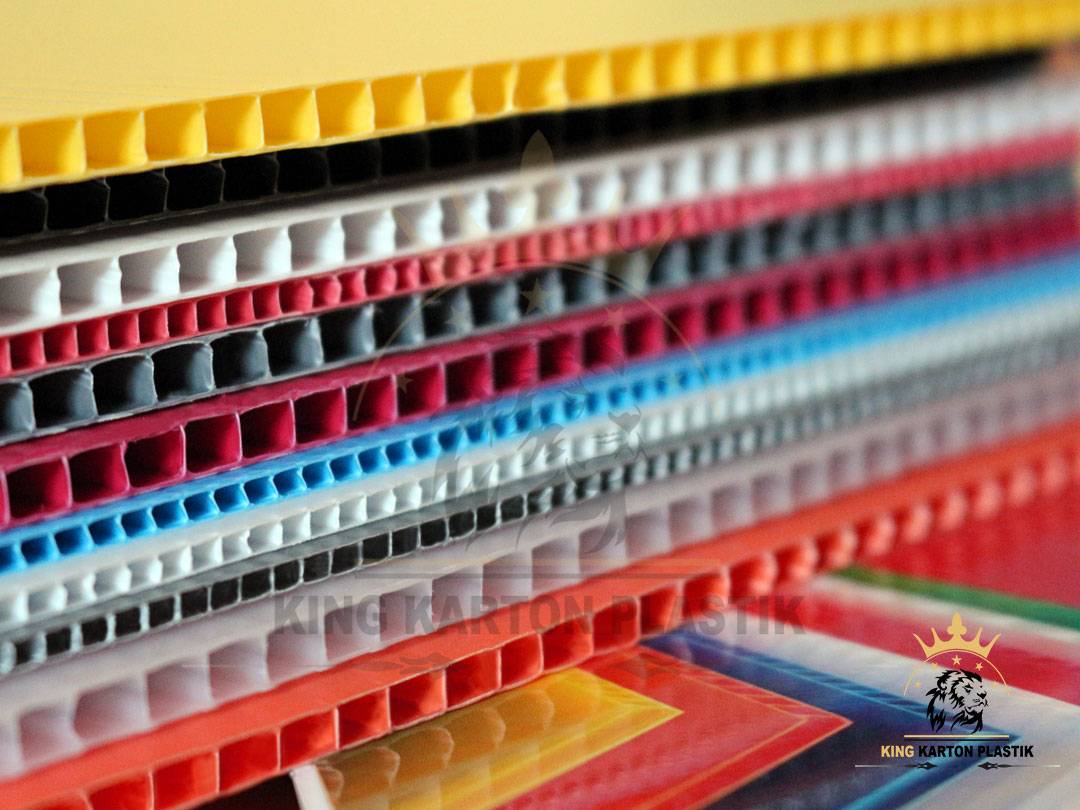

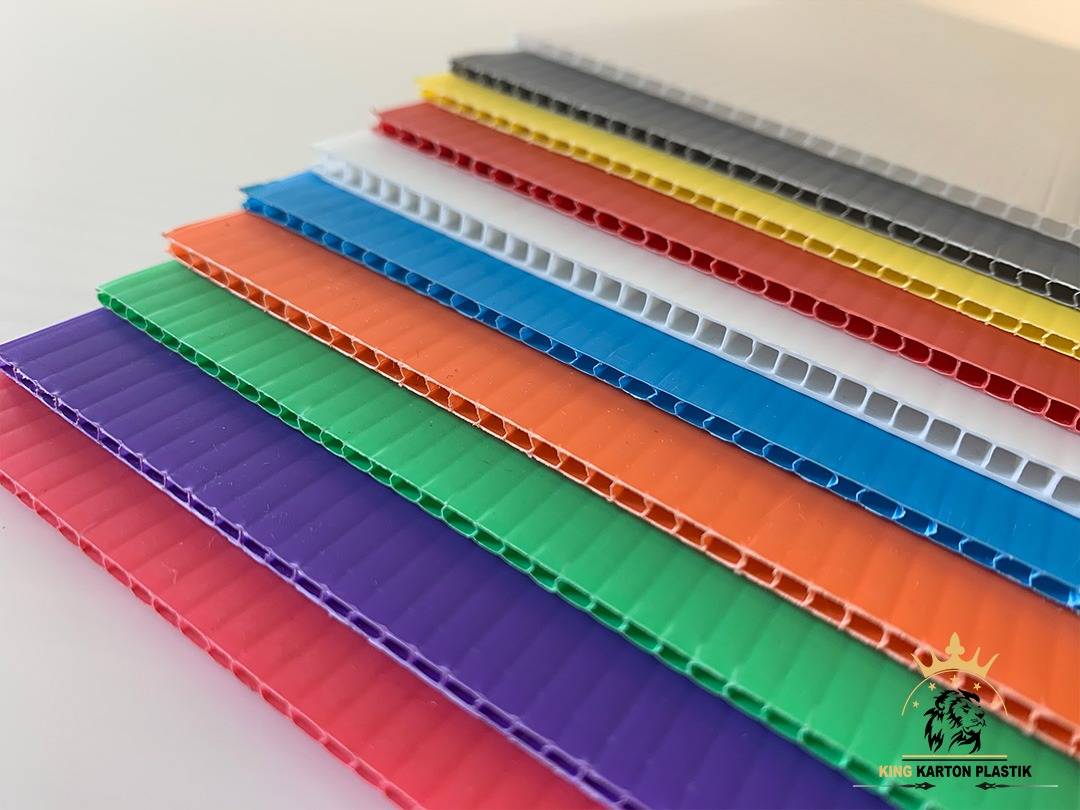

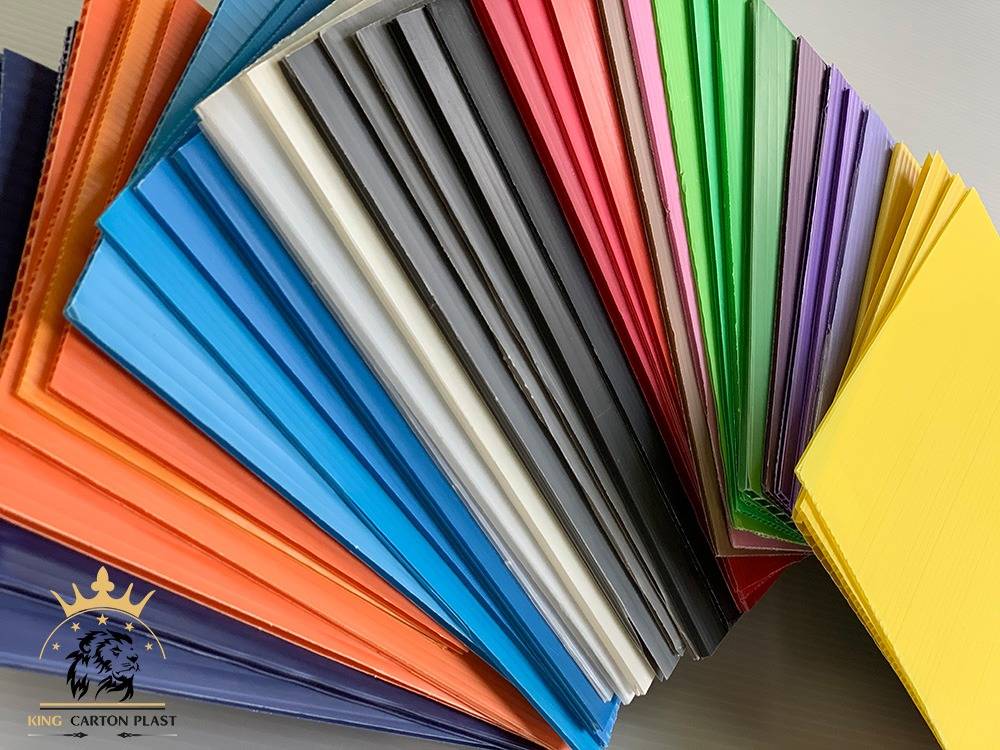

Plastic Sheets have a fairly high variety of colors and the normal thickness of these sheets in the market is between 2 to 12 mm. This product is on the market PP Sheet is known as Corrugated Plastic Sheet, PP Corrugated Sheet or Haloprofile Sheet. It can be combined and used with glass fiber to strengthen the texture of the plastic sheet.

Plastic Sheet application

Cardboard Plast has become a popular product in the chemical, agriculture, advertising, packaging and construction sectors, and one of the most important reasons for its applications is its high resistance to heat, pressure and impact, and its high resistance to chemicals.

Other positive points about this product include its incombustibility. Cardboard plast does not catch fire even under direct heat, it melts. Of course, it should be noted that plastic sheets made of polypropylene have good heat resistance.

In addition to being resistant to deformation and appearance, Plastic Sheet can be attached to other objects with staples, wire, wood glue and thermal glue.

Due to its light weight, Cardboard Plast can be easily transported in large quantities and therefore has many applications in construction and decoration design.

This is a suitable option for home or office decoration and the other reason is that this product is odorless and does not absorb odors from the environment.

One advantage that makes this product popular for construction and decor is its insulation.

Sheet Plast has high resistance to heat, cold, water and direct sunlight.

At a time when the development of industry is equated with the destruction of nature, Carton Plast seems to have made significant progress; because no toxic substances are used in its production and the final product can be recycled for reuse and does not need to be thrown away and pollute the environment.

Reasons for using plastic sheets:

- The plastic sheet has a very good resistance in different environmental conditions.

- Plastic sheet is resistant to water, various oils and chemicals.

- The strength of the plastic sheet is resistant to temperature fluctuations from minus 40 to plus 80 degrees Celsius.

- Plastic sheet with a maximum width of 210 cm is produced without length restrictions.

- Plastic sheet is available in thicknesses from 2 to 13 mm with a temperature of 300 to 3000 g/m2.

- Plastic sheet rolls can be produced in densities from 2 to 4 mm thick and in customized sizes.

- 36 color production variety, silk and digital printing possibilities are other advantages of plastic sheet.

PP Corrugated Flat Sheet

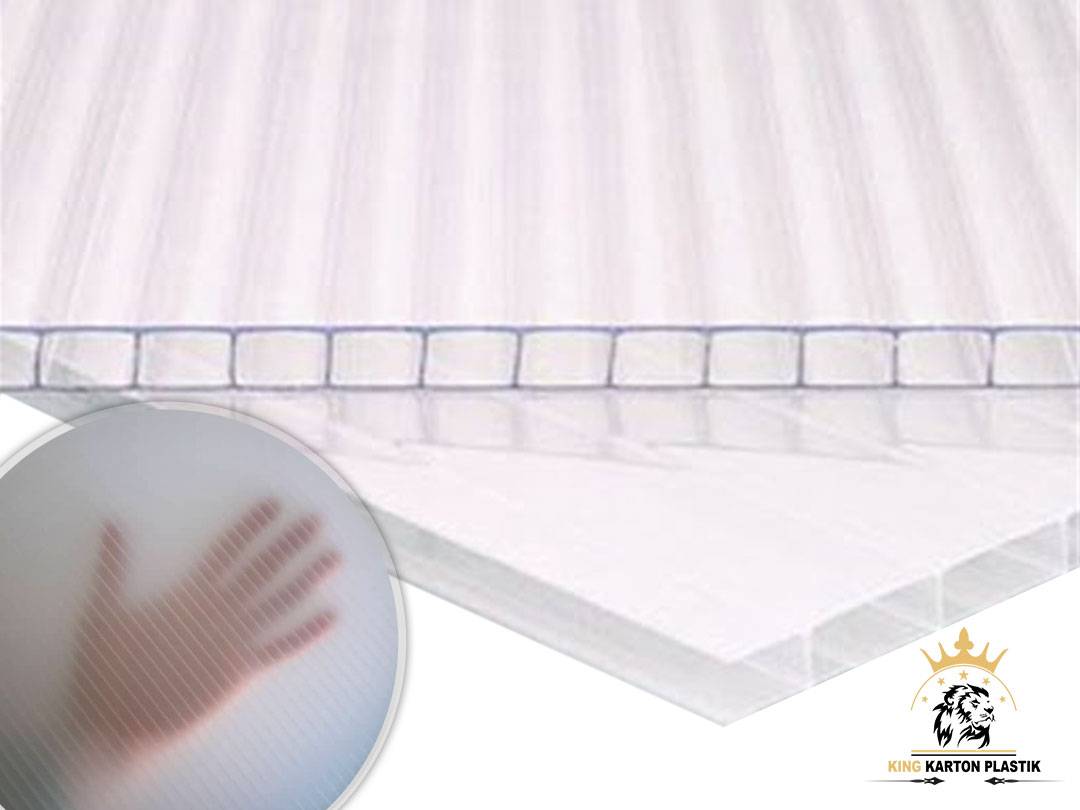

PP Corrugated Flat sheets are made of Polypropylene, no harm to the environment, recyclable and reusable. These sheets are produced by extrusion, consisting of two flat outer sheets (films) connected together in narrow vertical plates (flutes).

This product has many applications in more than 80 various industries due to its high physical and chemical durability and high resistance to thermal fluctuations.

PP Corrugated Flat Sheet is used in packaging, advertising, agriculture, white goods, stationery, pharmaceuticals, hangars, greenhouses, buildings, fruit boxes and similar sectors.

PP Corrugated Flat Sheet is also used in interior decoration due to its unlimited color variations. It is washable, flexible, high pressure resistant, non-toxic, odorless and lightweight, as well as stylish and modern in appearance.

What is PP Sheet or Polypropylene Sheet?

You may have seen the PP Plate around you many times, but you have no knowledge about it. For example, you may have seen PP Sheet in fruit shops as fruit boxes, waste bins, produce stands or fruit sorting classrooms. In this article, we will discuss exactly what PP Sheet aka polypropylene sheet is and what are its uses.

PP Sheet is made from a material called polypropylene, which gives it good strength to produce inflexible sheet-like products and can also be recycled in the same industry.

Besides PP Corrugated Sheet, this product is also known in the market by other names such as PP Sheet, flat sheet, Plastic sheet, Kroogit Plastic Sheet and Plast Sheet. Of course, it is noteworthy that the plastic sheet is produced by extrusion and consists of two flat outer sheets (films) connected to narrow vertical sheets (grooves).

Plastic Sheet Prices

Contact us to find out the plastic sheet price and get advice.

What materials is PP Sheet made of?

This product is mainly used in the advertising industry, agricultural industry, construction industry, packaging industry and chemical industry due to its physical durability and high chemical resistance and tolerance to thermal fluctuations between -20 and +80.

With the advancement of science and the influence of technology in various aspects of modern life, different industries have diversified the production of goods or replaced the existing goods with the new generation of more beautiful and hygienic products, effectively eliminating the entrepreneurs in the economic field by operating the largest Plastic Sheet production facilities in the Middle East with high annual production capacity of PP Sheet produced from polypropylene, the shortcomings of the packaging and advertising sectors with the use of the latest machinery in line with modern technology and technology in Europe today (PP), to ensure competition for Turkish goods in various markets, especially in the international arena.

Cardboard Plast products made from PP Sheet or Holoshit, whose raw material is polypropylene (PP), are not known in the market due to their novelty, so it has not been defined and proven to determine the reality of its use in various industries. Status.

The known advantages of Polypropylene Sheet are; effective flexibility and ductility, high compression and shearing ability and a variety of formulations resulting in 100% resistance to water, acids, edible and industrial oils and most chemicals and approval by the competent authorities for use in the food and pharmaceutical industries. The special feature of this product is that it can help all industries to reach target markets, attract customers and create unique competitiveness, and can be used in the manufacture of Plastic box, Plastic parcel, poly stand, Waste collection box, roplast and other advertising products. It is even used as a final product in various industries, including home appliances (behind the refrigerator), construction (molding and ceiling blocks), interior architecture (wall and ceiling coverings and partitions) and.... To be used.

PP Sheet advantages:

PP sheets are produced in thicknesses from 2 to 14 mm and in various colors. These sheets are mainly used in the packaging industry and are well suited for advertising, industrial, construction and agricultural uses. This product is like a die-cast cardboard box and is printed on it by silk screen method. Another feature of PP Corrugated Sheet is its high resistance coefficient against physical and chemical factors.

Properties of PP sheet:

Lightweight: The light weight of this product, equivalent in weight to one-sixth of glass and one-third of acrylic, is ideal for construction, decoration and ...

Different color types: This product can be produced in different colors.

flexibility: Polypropylene sinks have high flexibility and can be curved in both length and width. But it is better to make a longitudinal arch to avoid folding.

High-pressure telorans: This product can be used for packaging a variety of products because its ability to withstand high weight and high strength and its durability has created a dramatic change in the packaging industry.

Washable: This product can be washed with water and detergent and has no negative effect on PP sheets.

Non-toxic: No toxic substances were used in the production of this product and these sheets do not pose any danger to human health and can be used as food packaging; Note: Before use in the pharmaceutical and food industry, it is necessary to disinfect with one of the sterilization methods.

Odorless PP sheet is completely odorless and does not absorb the odor of its environment.

Printable: It is possible to print different patterns and colors on these plates with the Serigraph method and it is very durable, so it is a very suitable product for use in billboards and stands.

Easy cutting ability: Polypropylene sheet can be cut like cardboard cards with a simple knife or die-cutting machine and can even be combined with staples, glue, plastic welding and....

Maintain basic flexibility: This product (PP sheet) will maintain its flexibility and softness and keep its shape if not exposed to direct sunlight.

fireproof: These layers do not ignite at high temperatures but melt, so they act as a barrier in the event of an accident and prevent the fire from growing rapidly.

Impact and crush resistance: The strength and impact resistance of these sheets are very high. They are 200 times more durable than glass and 7.5 times more durable than acrylic.

Chemical resistant: The material of this product is propylene, so it is resistant to most chemicals. (Click here for details on these chemicals)

heat insulator : This product prevents heat from passing through and is widely used in the construction industry to prevent energy loss.

moisture insulation: These layers completely prevent the passage of water and moisture. Therefore, in greenhouses, swimming pools and ...

Sound insulation: This product can be used as sound insulation due to its network structure and the presence of air inside the plates.

Possibility of piping: PP sheet is flexible if produced at low temperatures and can be packed in rolls, taking up less space.

UV insulation: According to the customer's order, special materials are used in the production of this product, which block the passage of the sun's ultraviolet rays and greatly increase the resistance of this product to sunlight.

recyclable: This product is fully recyclable.

It has a global standard: This product is made entirely from standard materials approved by the FDA (US Department of Health).

Separator This product can be used as a product classification in longitudinal classes.

PP Sheet applications:

The different applications of PP Sheet in the sector due to its lightness, ductility, waterproofing, insulation, liquid impermeability have led to an increase in its use in the country's industries. Here are some of the main uses of PP Sheet.

Advertising Printing and advertising on PP Corrugated Sheet is one of the most effective advertising media. This type of advertising is highly cost-effective in terms of quality.

Packaging: Cartoons made with plastic kevha are very durable and impact resistant. Completely waterproof and hygienic. It also makes your packaging very elegant and beautiful.

Cover and roof: Cardboard Plast is completely hygienic, sound and heat insulation and moisture, does not harbor any fungi and bacteria and is very lightweight with easy installation. PP Sheet is used under the hangar roof to have a nice appearance and to act as a fiberglass holder.

PP Sheet is also used in various industries such as agriculture, automotive, stationery, construction, electronics, food, warehouses and dividers and many other applications.

By reading this article, you can now replace this product with old and relatively non-resistant methods and benefit from its resistance and unique properties, as well as beautiful and varied designs. Please leave us your comments and suggestions at the end of this article.